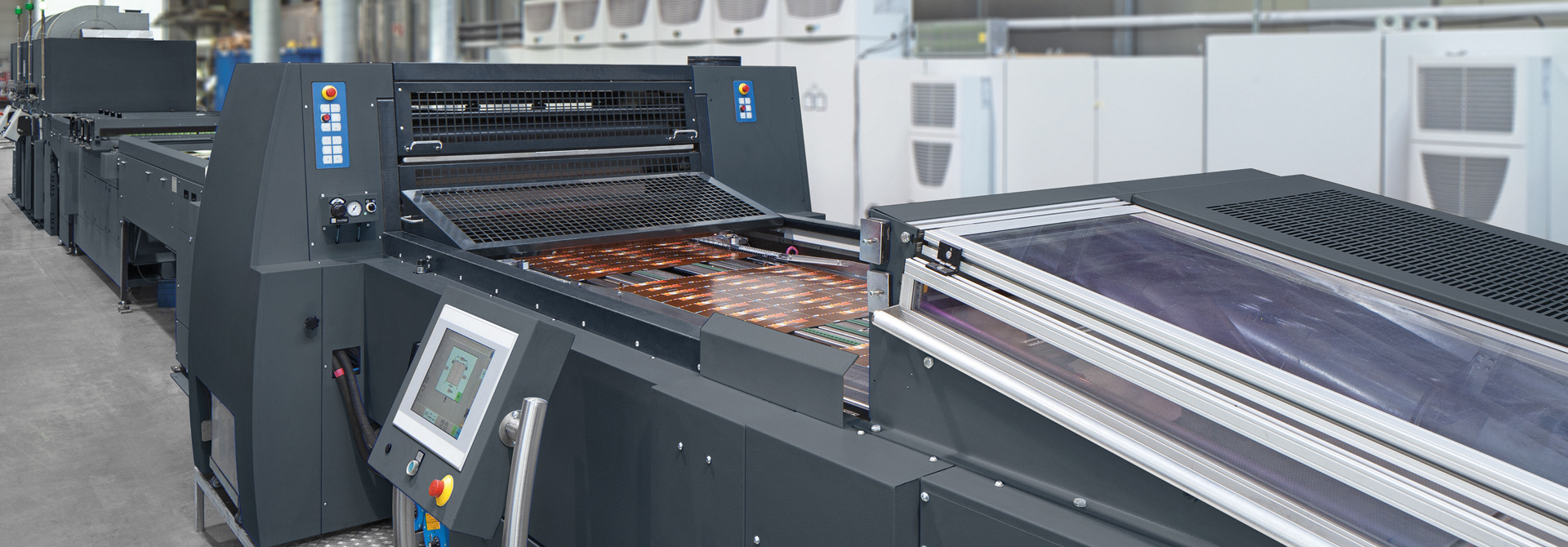

The perfect solution for UV inline coating

The MetalCoat 480 is ideally suited for the application of protective coatings within a UV printing line. As the most modern machine on the market for inline coating, it incorporates a whole host of cutting-edge technologies, including specialised coating application systems. The MetalCoat 480 rises to every challenge – irrespective of whether that means problematic coatings, demanding substrate qualities or increased speeds to match the overall line.

High speed – also for coating!

High productivity need not end at the delivery of the printing press. Through electrical synchronisation of the overall line and a consistent focus on maximised speed, the MetalCoat 480 is able to keep pace with the high production outputs of modern presses like the MetalStar 3 and Mailänder 280. Inline coating is no longer a bottleneck!

Innovative solutions of the MetalCoat 480:

- Electrical synchronisation of the overall production line

- Maximum coating precision thanks to dedicated drive technology

- Laser-assisted cylinder positioning

- Use of coating plate cylinder for UV coatings