Over 130 years of expertise in metal decorating

The origins of Koenig & Bauer-MetalPrint lie in the globally renowned companies Mailänder, LTG and Bauer + Kunzi. These three companies have been setting the standards throughout the history of metal decorating:

1876

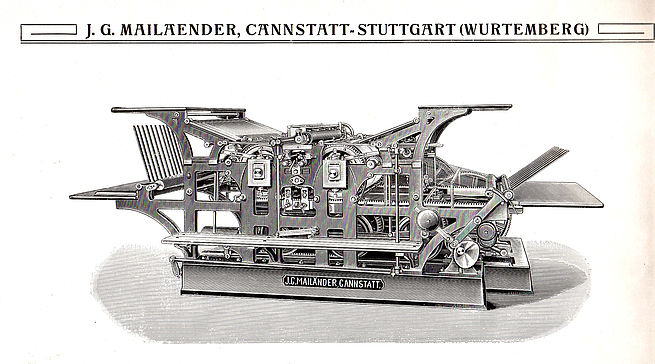

Founding of Druckmaschinenfabrik Mailänder, an instrumental step in the development of a metal decorating industry.

1888

Mailänder presents the first printing press designed specifically to handle metal sheets. The world-famous Mailänder press, which has seen constant further development through to the present day, stands for reliability, a robust construction and repeatable printing results.

1924

Founding of “Cärrier Lufttechnische Gesellschaft”, later renamed LTG Lufttechnische GmbH, as a manufacturer of air conditioning systems for various branches of industry in Stuttgart.

1926

Mailänder develops the first coating machine for metal sheets.

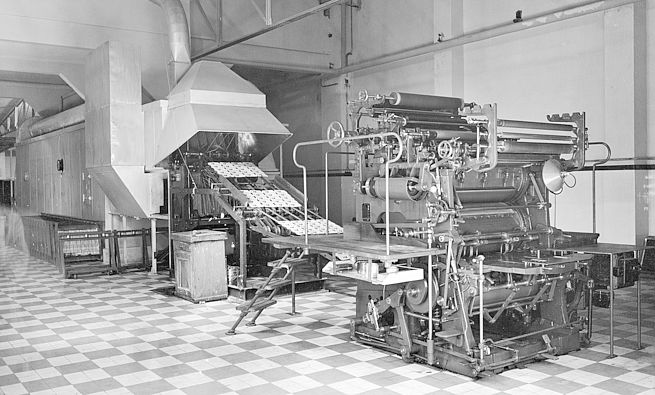

1932

LTG enters the metal decorating market with the first drying oven for metal sheets, used to produce the famous blue Nivea Creme tin for the skin care company Beiersdorf from Hamburg. The photo shows a Mailänder metal decorating press with the LTG drying oven.

1974

Founding of Bauer + Kunzi as a supplier of metal decorating presses in Ditzingen near Stuttgart.

1994

LTG Lufttechnische GmbH and Mailänder merge to form LTG Mailänder, the first system supplier for complete, cost-effective and environment-friendly metal decorating lines with integrated air purification, a technology which LTG has supplied since 1965.

1995

Bauer + Kunzi launches the MetalStar 1, the first metal decorating press in modular unit design. It is the outcome of cooperation with KBA-Planeta, the market leader for large-format sheetfed offset printing presses, and heralded a new era of high-speed multi-colour printing with production outputs up to 10,000 sheets per hour.

2002

Launching of the MetalStar 2, also known as the MetalStar PR. It is sold around the world in numerous configurations, including an eight-colour version with integrated dryer tower for UV coatings.

2003

Bauer + Kunzi is taken over by Würzburg-based KBA, a leading manufacturer of paper printing presses. This enables KBA to enter the metal decorating market and to expand its product portfolio accordingly.

2006

LTG Mailänder is taken over by KBA subsidiary Bauer + Kunzi, which is subsequently renamed KBA MetalPrint.

2008

Launching of the Mailänder 222. It continues the success of the Mailänder 122 series and offers not only a larger print format, but also many automation features such as semi-automatic plate changing.

2013

With development of the Mailänder 280, KBA-MetalPrint brings together the best of two worlds – proven Mailänder technology combined with the high-performance printing units of the MetalStar series.

2014

KBA-MetalPrint launches the energy-saving HighEcon drying oven, the first drying oven in the world which can handle sheets down to a thickness of just 0.100 mm. At the same time, cutting-edge technologies enable gas consumption to be reduced by up to 70%. This innovative development earns KBA-MetalPrint a Silver Metpack Innovation Award.

2014

The triumphal march of the MetalStar series continues with the launching of the new MetalStar 3. This press offers the highest-ever level of automation and stands for absolute state-of-the-art technology. It is the fastest metal decorating press on the market.

2021

Even more effective, equipped with the latest features, the new MetalStar 4 presents itself in an exclusive modern design. It continues to set the performance benchmark in terms of production speed and makeready times in metal printing. It therefore remains what it has always been: the most innovative and modern high-performance press in metal decorating.