The modular exchange system (ModEX) from Koenig & Bauer MetalPrint opens the coating line to an automated and smart way of coating metal sheets.

Modularity for maximum flexibility

As the demands and ideas around digitalisation and automation are different from customer to customer, ModEX is designed in a completely modular way. This means the customer can decide which exact functionality he wants to use. Also, it is possible to add additional modules at a later stage. This allows the customer to grow and learn with the new possibilities ModEX has to offer.

Base module

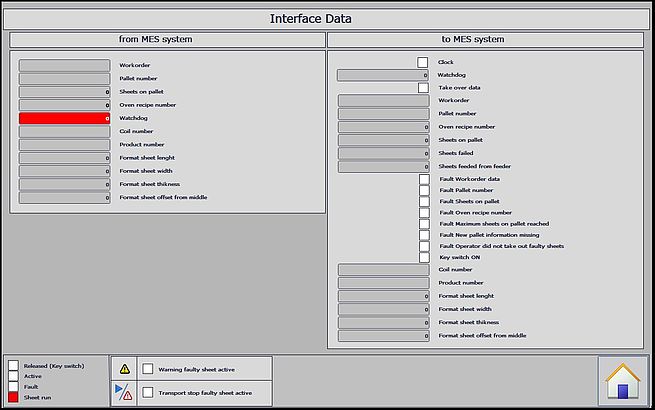

The base is the so called “ModEX: Base module”. It opens all single machines, which are used in a coating line, to connect with the customer MES, PPS or MIS system. The interface used for this is the OPC-UA standard, which is an industry wide common interface for machine connections. The coating line is being equipped with an OPC-UA server, which is additionally secured with an integrated firewall secures the machine network from the shop floor or customer network.

Being equipped with this technology, every machine is now able to provide machine messages, fault messages and actual values in real time to the customer system. With the base module, the communication between coating line and customer system is uni-directional.

Data exchange to customer system

With the “ModEX: Data exchange module (DEM)” ModEX establishes a bi-directional communication to the customer system. This allows ModEX to receive information about the next upcoming production job. The job information can consist on various parameters such as:

- Sheet format

- Sheet thickness

- Production number

- Job number

- Oven temperature

- Fan frequencies

- Amount of sheets overall

- Amount of sheets per pallet

All the information for the next upcoming job has to be provided by the customer system to ModEX shortly before the next job start.

Beside the information from the base module (machine messages, fault messages, actual values) the data exchange module provides much more information back to the customer system. Such as:

- Sheets per pallet

- Palle

- Overall sheets

- Gas consumption

- Oven temperatures recorded during production

All information are automatically provided to the customer system at the end of each job. The operator can focus on the production, as ModEX is providing the information completely automatic.

Cost reduction due to automation

One of the biggest cost factors in production is still the operator. It is no surprise, that robot – technologies or camera based systems are on the rise to support the operator and to accelerate processes. ModEX takes this kind of automation to coating lines.

This begins with an automatic start and stop of production depending on the sheets per job, an information which is transferred by the customer system to ModEX. This means that ModEX will stop the sheet feeder, as soon as the needed amount of sheets is being fed to the production line. If a double or triple stacker is installed, ModEX even changes the stacking box as automatically as soon as the desired amount of sheet per pallet is being stacked. The amount of produced sheets is now not depending on the operator anymore.

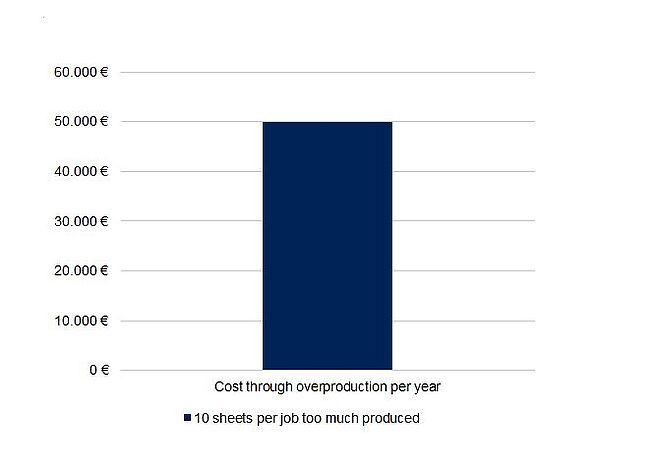

Considering a yearly production of 5.000 jobs and a sheet cost of 1,00 €, this graph shows the savings per year if the operator produces10 sheets more than he actually should.

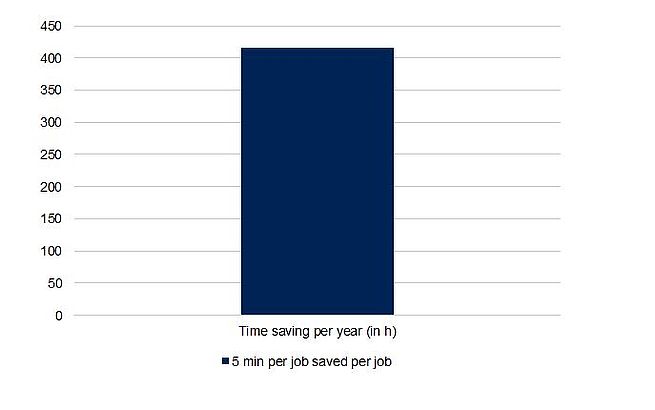

A part of the make ready of a coating line are processes like the setting of different machines to new parameters or documentation of production data. As ModEX performs this tasks automatically via the communication to the customer system, the operator can save time and increase the production time per year.

Considering here also 5.000 jobs per year, the time savings are significant. The chart shows time saving per year for 5 minutes saving per job.

A “smart” and self setting line

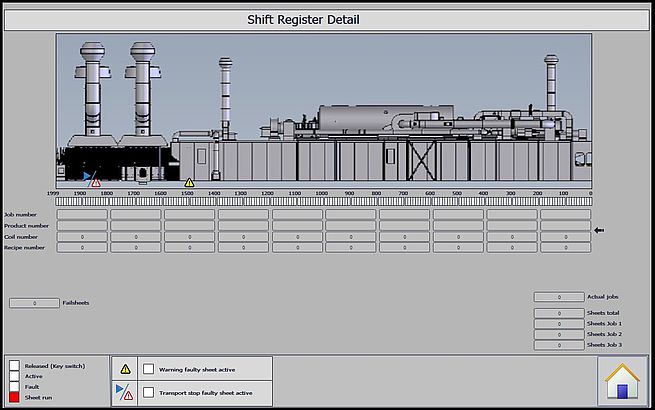

As all machines in the production line are connected to ModEX, the state of each machine is clear to the system at any time, which is also displayed at the operator screen from ModEX.

The shift register displays which job is now in which part of the line and which parameters are set on the corresponding machine. With this information available, ModEX is now able to perform make – ready processes without the interaction of the operator.

As an example: Job 1 is being coated at the moment. The required temperature in the heating zone is 200 °C. The next job provided by the MES is Job 2, which requires a temperature in the heating zone of 210 °C.

ModEX will now automatically start the rise of temperature in the heating zone as soon as the last sheet of Job 1 left the heating zone, in order to lose no time during the make ready process. Again, all without the interaction or delay of a manual action by the operator.

Having this kind of technology available, the vision to a smart, self-adjusting line comes closer.

Base for future developments

ModEX builds the start for an automation and digitalisation strategy from Koenig & Bauer MetalPrint. With more modules for ModEX being in development and design right now, the range of functionalities and upgrades will extend.

ModEX is available for new coating and printing lines. Also, retrofits are available on special request.