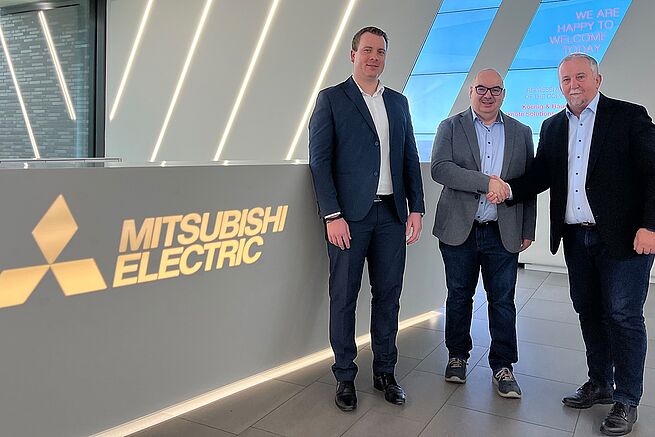

Mitsubishi Electric, a leading provider of contact image sensors (CIS), and Koenig & Bauer, a pioneer in industrial print applications and inline machine vision systems for various applications, signed a letter of intent for their future cooperation. The aim of the strategic partnership is to combine the strengths of both companies in order to offer standardized, high quality machine vision components to the field of electrode foil production for battery cells.

By integrating Mitsubishi Electric’s CIS and Koenig & Bauer’s illumination units and embedded frame grabbers, the partners will create various modules that can achieve perfect imaging conditions for electrode foil surfaces, which are challenging to inspect with conventional, available setups.

The modules will enable battery cell manufacturers to improve their production efficiency, reduce their failure rate, and ensure the safety and reliability of their products and are going to reduce integration efforts. The modules will also be compatible with electrode foils for various battery cell types, such as pouch, cylindrical, or prismatic, and can support different production processes.

Mitsubishi Electric and Koenig & Bauer’s partnership is a response to the anticipated rise in demand for lithium-ion batteries due to the increasing popularity of electric vehicles as well as growing requirements in the consumer electronics industry and power grid. According to calculations by the Boston Consulting Group, the supply of lithium-ion batteries will have to increase tenfold by 2030 to meet the market needs. Machine vision is a key technology that can help battery manufacturers achieve this goal by enhancing quality control and automation capabilities while also reducing waste rates, and therefore contributing to sustainability targets and cost reduction.

“We are excited to partner with Koenig & Bauer and bring our innovative machine vision solutions to the battery cell production industry in standardized modules, as this will decrease integration efforts ” said Martin Messy, Director CIS at Mitsubishi Electric. “We believe that our CIS, combined with Koenig & Bauer’s illumination units, will offer a unique value proposition to our customers and help them overcome the challenges of inspecting electrode foil.”

“In partnership with Mitsubishi Electric, we are applying our extensive experience in the development and construction of printing machines as well as inline and offline machine vision systems for quality control to this application,” said Julian Schubert, Vice President of Data, Vision and Authentication Solutions at Koenig & Bauer. “We are confident that our high power illumination units, our own embedded frame grabbers, integrated with Mitsubishi Electric’s CIS, will provide optimal imaging conditions for battery cell inspection and enable our customers to produce safer and more reliable battery products.”

Based on initial joint projects, CIS sensors from Mitsubishi Electric are already being used successfully in combination with illumination units from Koenig & Bauer in various markets. The partnership is the next logical step to leverage synergies and provide value added solutions to a fast growing market segment.